Introduction

Ramjets are a missed opportunity for everyone who wants to move things at faster than the speed of sound.

- They can have very good fuel consumption (lbm fuel/lbf thrust) making them very inexpensive to operate in their natural regime.

- They are extremely simple making them inexpensive to build and maintain.

- They are scalable (come in all sizes).

- They are capable of very high speeds.

In the 1950’s the X-7a, using a modified Bomarc engine, flew at Mach 4.3. In the early 1980’s the ASALM hit Mach 5.5 when the fuel control stuck open.

Textbooks estimate that ramjets can operate to Mach 7 with normal mixture ratios and knowledgeable propulsion engineers estimate that speeds greater than Mach 9 (possibly as high as Mach 20) can be achieved by running very fuel rich and/or using water injection.

The major drawback for ramjets is that they produce no thrust at zero speed. In fact, they produce little thrust and are very inefficient until they get up to high subsonic speeds. On the other hand, they have been operated as low as 250 mph (ref Casamasa & Bent, _Jet_Aircraft_Power_Systems_, 1965, McGraw-Hill. The early Bomarc ramjet was rated as operating between Mach 0.7 and 1.5 (ref _Janes’_All_The_World’s_Aircraft_”). Thrust and efficiency increase as speed increases and peak between Mach 3.5 and and 4.5. Later Bomarc engines weighed under 300 lbs and were rated at over 12,000 lbs thrust. According to one report the Isp of ramjets exceeds that of oxygen/kerosene rockets at about 500 mph.

The following are ways to get a ramjet started without the use of a large rocket motor.

How to Start A Ramjet

There are several ideas offered below. Each has it’s merits and drawbacks. I recommend you at least scan them all.

Once a ramjet is started a spacelift vehicle can achieve nearly half orbital velocity significantly reducing the expense of placing satellites in orbit.

Powered Dive From Altitude

Model airplanes with piston engines and small jet engines are currently being clocked at 200-250 mph at ground level in horizontal flight. Propeller driven aircraft, like the WWII P-58 Mustang, could hit 450 mph.By mounting a small ramjet on one of these aircraft and taking it to altitude, say 5,000-7,000 ft then going into a powered dive a subsonic ramjet will start producing thrust. This becomes a recursive situation. The faster the aircraft flies the more thrust from the ramjet, the more thrust the faster it flies, and etc. Somewhere above the ground the aircraft pulls out of the dive and begins to climb under the power of the ramjet.

Variation 1 – The ramjet could be part of a second stage and release from the first making a lighter and aerodynamically cleaner upper stage.

Dive From a Mountain Top

This is similar to a powered dive from altitude but can be done without the piston engine. The ramjet powered vehicle can be shoved off the side of a mountain top so it can go into a steep dive. Dropweights (even water) can be added to help gain speed in the dive. The weights can be released once the vehicle begins to level off and climb. This would allow the vehicle to be designed better for high speed (such as a waverider).

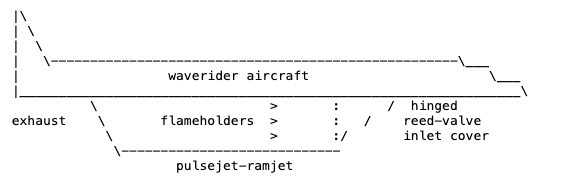

Pulsejet/Ramjet With Retractable Reed-Valve Inlet Cover

By placing an inlet cover with reed valves, like a pulse jet, in front of the ramjet the jet can be operated at zero speed. The jet would operate in pulsejet mode until high enough speed is gained then the inlet cover is hinged up and out of the way to allow free stream air flow through the ramjet.

Tube Launch With Sucked Air

To get a ramjet to operate air must flow through the engine at high speed. One way to do this is to place the vehicle in a tube and produce a partial vacuum at the tail end of the tube while holding the vehicle stationary. This will cause the air to flow down the tube and through the engine. The engine can then operate and accelerate along the tube. This would probably take a very long tube and a powerful vacuum pump.

Tube Launch With Blown Air

This is similar to the previous concept except that air is blown down from the head end. This increases the air density and thrust of the ramjet but this will probably still take a 1-2 mile tube.

Variation 1 – Use a large blower to suck air from the tail end and blow it into the head end like a continuous wind tunnel.

Tube Launch With Pressurized Air In Tube

With the vehicle in the tail end of the tube and both ends capped off the tube can be filled with high pressure air. At launch time the tail end of the tube is opened and the high pressure/density air is forced through the ramjet at high speed. This higher density air should significantly increase the thrust of the engine. The cap at the head end must be removed just before the vehicle reaches it or both will disintegrate.

Variation 1 – By using a mixture of helium and oxygen (as opposed to nitrogen and oxygen in normal air) the thrust can be increased slightly (due to the higher exhaust velocity of the lower mass helium) while the aero drag drops significantly. Most of the helium can be recovered intact.

Variation 2 – By using a less-than-stoichiometric mixture of fuel and air in the tube the vehicle can use less fuel and therefore be made smaller and lighter. This is because only a small amount of fuel needs to be added to create a combustible mixture in the ramjet. This is very similar to what is done with ramtubes.

Variation 3 – As the air enters the tail end inject fuel and burn it like an afterburner. This will help increase the air pressure and the speed of the air behind the piston.

Tube Launch With Air Pressure Driving A Piston

In this method the launch vehicle is on top of a piston or inside a sabot. Pressurized air from a large tank is dumped into the tube behind the piston. The ramjet will start once it leaves the tube. (see example below)

Variation 1 – Inject high temperature air into the tube ahead of the launch vehicle just before launch to reduce the density and increase the speed of sound. If filled with fuel/air and exploded like a pulsejet the hot gasses will essentially evacuate the tube ahead of the launch vehicle. The air used to drive the piston can also be heated to increase it’s speed in the tube and reduce the amount of air or pressure required.

Variation 2 – Place the launch tube inside a larger tube where the pressurized air is stored. Add pressure relief valves along the launch tube with optical sensors that open the valves after the launch vehicle has passed. This will reduce flow losses and maintain pressure.

Variation 3 – Segment the double tube design for ease of manufacturing, transportation, and maintenance. Some of the segments could have low pressure air, some high pressure air, some superheated water for steam. An amateur group could build one of these with PVC pipe using water heater elements to heat the water.

Variation 4 – If the head end of the tube is deep in water, the high water pressure could be used to compress air or directly drive the vehicle.

Tube Launch With Steam Pressure

This is similar to Tube Launch With Air Pressure with the exception that high pressure steam is injected behind the vehicle rather than air. The advantage is that it can be built with smaller, more readily available parts. High pressure boilers are standard commercial items. Super-heated water (under high pressure) can be injected directly behind the piston where it can expand to 20-100 times its volume with no additional heat addition. Of the tube launch concepts this is probably the most doable for startup companies.

Note: Achieving Mach 1 (~1000 fps) takes both high G loads and/or long tubes. For example at 100 G it would take a 150 ft tube. At 10 G it would take a 1,500 ft tube. This seems very long except when compared to the California Aquaduct which runs about 200 miles. The new water tunnel from the Catskill Mountains to New York City will be 135 miles long, 10-24 ft in diameter, and run as deep as 800 ft below the City. Some mine shafts extend vertically down 10,000 ft.

Note: High pressures may not be all that necessary. For example, a 12 inch diameter tube has 113 square inches of area. At 100 psi this is 11,300 lbs of force. A 100 lb vehicle will experience an acceleration of 113 G with this force. Household water pressure is about 40 psi and many pipes are designed for 80-200 psi. Garage sized air compressors go up to 125 psi.

With 10 sections of 12 inch PVC, a compressor purchased at the local K-Mart, a large tank for the compressed air (possibly made of PVC), and some small hardware available from the local hardware store and you too can (theoretically) accelerate a 100 lb vehicle to 800 fps. Conversion losses and aero drag may keep it down to 600 fps. Launch rate would depend on the size of your air compressor.

Note: Tubes can be made up of a variety of materials such as PVC, aluminum, and steel.

Where To Get Long Straight Runs For A Tube

Mine shafts, existing or new

Long straight-sided mountains, canyons, or ravines

Flat level ground (horizontal takeoff only)

Deep lakes and oceans (the high water pressures can be used in various ways to advantage). Oceans are exceptionally good because

Safety – no one to hit

You can launch from the equator, the arctic, or any latitude

The air is dense allowing the ramjet to develop high thrust at the beginning of the flight.

Ground Launched

There are many ways that a small vehicle can be launched from relatively flat ground. Here are a few.

Variation 1 – Atop a race car. While this is not recommended due to safety reasons it is not unusual for some race cars to exceed 250 mph. In February, 1993, the In & Out Burger Funny Car ran the quarter mile in 5.06 seconds hitting 294 mph. Special race cars have recently broken the speed of sound.

Variation 2 – Unmanned sled. Sleds come in many types. A couple have been proposed for launching 250,000 lbm space ships (RASV). Sleds can be accelerated via propellers, pulsejets, or pulley cables. In a pulley arrangement a cable (or rope) is wrapped through a couple of n-wheeled pulley with the loose end tied to the sled (or vehicle). One of the pulleys is held stationary while the other is attached to a truck or some other pulling device. When the truck pulls the pulleys apart the loose end of the rope will move at a speed n-times the number of wheels. IAW, a 10 wheeled pulley arrangement being separated at 25 mph will draw the loose end at 250 mph.

Between Nevada and California going into Mono Lake there is a 21 mile stretch of road that is laser straight and downhill all the way. The launch vehicle just has to turn sharp at the bottom to avoid the 14,000 ft mountains. Many other straight roads are also available.

Here are some sleds that can be made relatively easily.

Variation 2a – Wheeled. A wheeled sled, with special wheels, can be accelerated to several hundred mph.

Variation 2b – Hovercraft or ground effect sled.

Variation 2c – Abandoned railroad track. This has the advantage of being very level and very straight. With a little effort the joints between the tracks can be leveled making for a very smooth, controlled sled run. The disadvantages are that railroad tracks often have poles and wires along side them. Another disadvantage is that sometimes the tracks aren’t so abandoned.

Variation 3 – Bullet Train. The Train A Grande Vitesse (TGV) bullet train in France currently runs up to 200 mph (ref: “Scientific American,” Oct 97, pg 100). A 40 ft catapult capable of accelerating a launch vehicle at 10 G carried on this train could add another 110 mph for a total of 310 mph.

Variation 4 – Regular Train. Normal freight trains travel the US at speeds of 80-100 mph. A 160 ft catapult (10 G) would add another 220 mph for a total of 300-320 mph.

Variation 5 – Navy Aircraft Carrier Catapult (possibly requiring pulley arrangement).

Centrifugal Launcher

Variation 1 – Swing the launch vehicle around in the horizontal plane on the end of a strong cable. Pulsejets in model airplanes have been clocked at 200 mph on control lines.

Variation 2 – Swing the launch vehicle around in the vertical plane from a bridge across a deep canyon. At the bottom of the swing it should be moving quite fast. A variation would be to wrap the cable around the bridge a few times so that each loop gets longer as the vehicle unwinds and accelerates.

Trebuchet

The trebuchet was first used about 300-400 BC by the chinese. The payload weight and speed are dependent on the size and configuration of the trebuchet.