Fundamental Principle

The fundamental principle of what I call the “Rimfire” engine is the use of small ramjet, pulsejet, or pressurejet engines mounted at the blade-tips of a fan or outer rim of a wheel. This is a variation on the ramjet powered helicopters built since World War II and advertised in magazines like “Popular Science.”

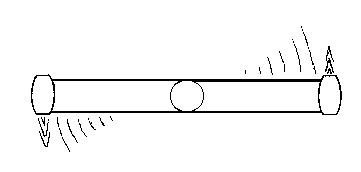

Below is a graphic representation of how this is implemented on helicopters. Small ramjets are mounted at the ends of the rotor blades. When the blades are spun up to high speed the ramjets begin operating and provide thrust to keep the blades turning. Typical tip speeds for helicopters and turbofan engines is Mach 1, or 1000 fps.

The advantage of this type of helicopter was the much simpler and lighter ramjet engines as opposed to piston or turbine engines. The disadvantages were poor fuel efficiency and very loud noise.

Expounding on the Advantages

If the disadvantages can be overcome there are several areas where such engines can dramatically improve the way we do things. The fundamental principle can be scaled up or down almost without limit.

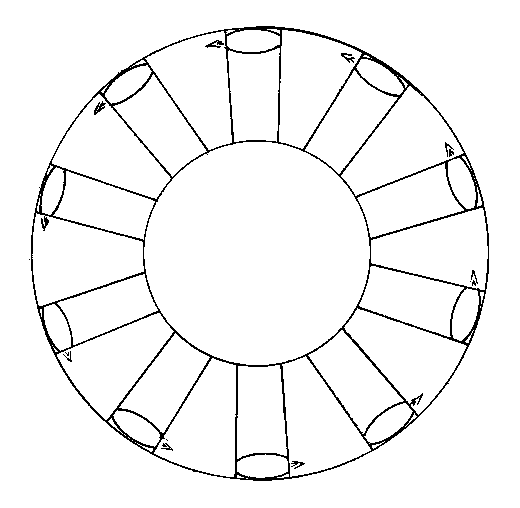

- Small ramjet engines could be mounted at the ends of fan blades forming an engine (see graphic) that would fit within the short fan section of a turbofan engine. The ramjet powered engine would be only a few feet long and weigh 1/10th the original.

- This could be exceptionally useful for super- and hypersonic aircraft such as the SR-71 where most of the flight is conducted in ramjet mode. The SR-71 engine is a co-axial turbo-ramjet. During low speed operation (takeoff and landing) the turbojet provides the thrust. As the aircraft goes supersonic some of the inlet air is ducted around the turbojet and into the afterburner section, thereby becoming a partial ramjet. At cruise speed (Mach 2.5-3+) all of the inlet air is ducted past the turbojet and into the afterburner thereby becoming a full ramjet. All this requires a large and heavy turbojet and complex/inefficient ducting just to get the aircraft up to ramjet speed.The rimfire engine, a much smaller and lighter engine (though, by itself less efficient) could replace the entire turbojet and complex ducting. Here it would provide thrust to get the aircraft moving and airborne. As the aircraft increased speed the afterburner would begin operating. Once the aircraft is well supersonic the rimfire engine ramjets would be shut down and the fan blades feathered into the wind allowing simple and efficient ramjet operation to power the aircraft through the majority of it’s flight. This would mean much lighter engines and aircraft with overall higher fuel economy.

- The rimfire engine concept could be a low-cost replacement for the expensive commercial engines used in home-built aircraft.

- The fundamental principle could be used as a portable generator. The power output can be calculated as:

10 ramjets @ 10 lbf thrust = 100 lbf total thrust Assuming a Mach 1 tip speed (approximately 1000 ft/sec) 100 lbf x 1000 ft/sec = 100,000 ft-lbf/sec 100,000 ft-lbf/sec / 550 (ft-lbf/sec)/horsepower = 182 horsepower At 5 1/2 ft in diameter the rotation speed would be 60 Hz. The engine thickness could be less than two feet. Variations include smaller diameter, more ramjets, and more powerful ramjets.

Associated Notes

- The Marquardt MA-12 ramjet that powered the early Bomarc missiles weighed 78 lbm and produced 12,000 lbf thrust. This engine was rated to operate from Mach 0.7 to 1.5. Later ones were rated to operate from about Mach 1.0 to 2.5.

- In the early 1960s ramjets mounted on the wingtips of an F-80 were operated as low as 250 mph, well within the reach of some race cars.

Noise Reduction

By mounting the rimfire engine inside a duct most of the noise can be dampened. In this manner they should be no noisier than piston driven engines.